Industrial Tank Insulation

Maintain optimal tank temperatures, reduce energy costs, and ensure workplace safety with MultiService’s expert industrial tank insulation. Our customized solutions address your specific needs, minimizing heat loss or gain for peak efficiency. This translates to significant energy savings, precise temperature control for reliable processes, and a minimized risk of burns for a safer work environment. Contact MultiService today for a free quote and discover how we can optimize your tank performance and savings!

Industrial Pipe Insulation

Reduce energy costs and create a safer work environment with professional industrial pipe insulation services from MultiService. Our commercial pipe insulation solutions minimize heat loss or gain, ensuring optimal temperatures for your processes. This translates to significant energy savings, improved efficiency, and reduced risks of burns for your employees. Contact Multiservice today for your industrial or commercial pipe insulation needs!

Industrial Vessel Insulation

Achieve peak performance and maximize energy savings with MultiService’s industrial vessel insulation services. We design and install customized solutions to perfectly suit your specific vessels, optimizing internal temperatures for efficient operation. This translates to reduced energy consumption, enhanced process stability and product quality, a safer work environment with minimized burn risks, and a lower environmental impact. Contact MultiService today for a free quote or click to learn more and discover how vessel insulation can optimize your facility’s operations.

Industrial Insulation Resources

The Ultimate Guide to Industrial Insulation

To take advantage of the benefits of industrial insulation, you need to know the properties of different materials, application details for the insulation, and the end goals to accomplish. Read on to learn more about industrial insulation.

Benefits of Industrial Insulation

Insulating materials provide high returns on capital investments through energy savings, process efficiencies, and even environmental stewardship. Click the button below to learn about the many benefits of industrial insulation.

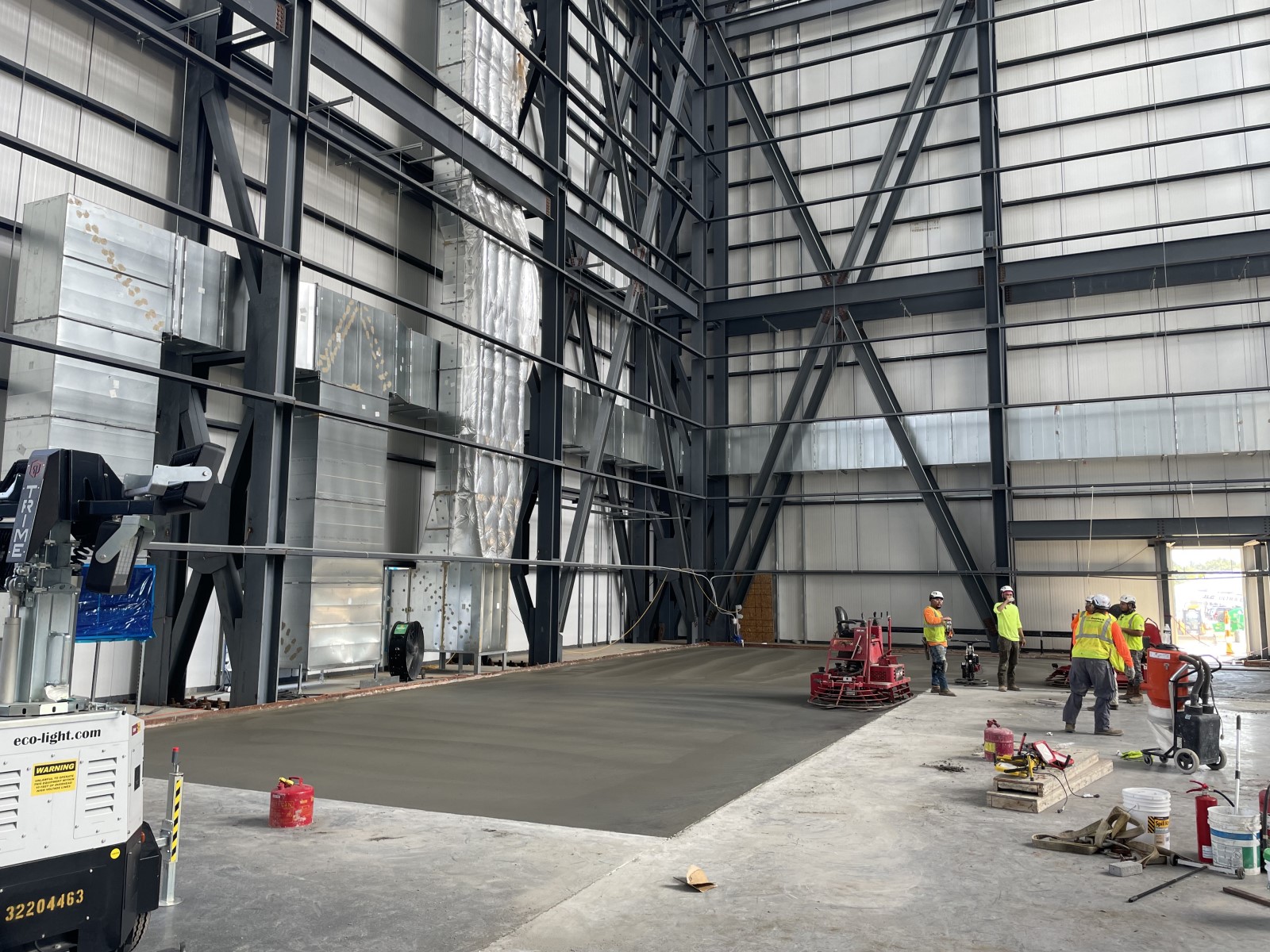

Case Study: Large Industrial Pipe Insulation Project for Hospital

Henrico Doctor’s Hospital came to Multiservice Industrial with a commercial piping insulation application with uncommonly large piping and strict scheduling. Click the button below to learn about the solution we provided.