Cut Energy Costs & Protect Your Building with Expert Commercial Insulation

Maximize energy efficiency, reduce operational expenses, and create a safer, more comfortable environment with tailored insulation solutions designed for commercial and industrial facilities.

With over 30 years of industry experience, MultiService Industrial delivers high-performance insulation that meets the unique needs of your facility. Our team ensures fast, professional installation with minimal disruption to your operations.

Top Commercial Insulation Benefits

Energy Efficiency & Cost Savings

Reduces heating and cooling costs by minimizing energy loss, leading to significant long-term savings on utility bills.

Improved Comfort & Temperature Control

Maintains stable indoor temperatures, creating a more comfortable environment for employees, customers, and equipment.

Noise Reduction

Helps dampen sound transmission between areas, improving privacy and reducing noise pollution in busy commercial settings.

Enhanced Safety & Compliance

Provides fire resistance and moisture control, helping meet building codes and protecting structural integrity.

Why Insulate?

Proper commercial insulation is one of the smartest investments you can make in your building. It lowers energy costs by improving thermal efficiency, keeps indoor temperatures consistent year-round, and reduces wear on HVAC systems. Insulation also dampens noise, enhances workplace comfort, and helps meet safety and building code requirements. Whether you’re operating a warehouse, office space, or manufacturing facility, quality insulation adds value, saves money, and protects your investment.

Common Applications for Commercial Insulation

Commercial insulation plays a critical role in improving energy efficiency, maintaining temperature control, and enhancing safety across a variety of systems and spaces. Here are some of the most common applications:

Commercial insulation plays a critical role in improving energy efficiency, maintaining temperature control, and enhancing safety across a variety of systems and spaces. Here are some of the most common applications:

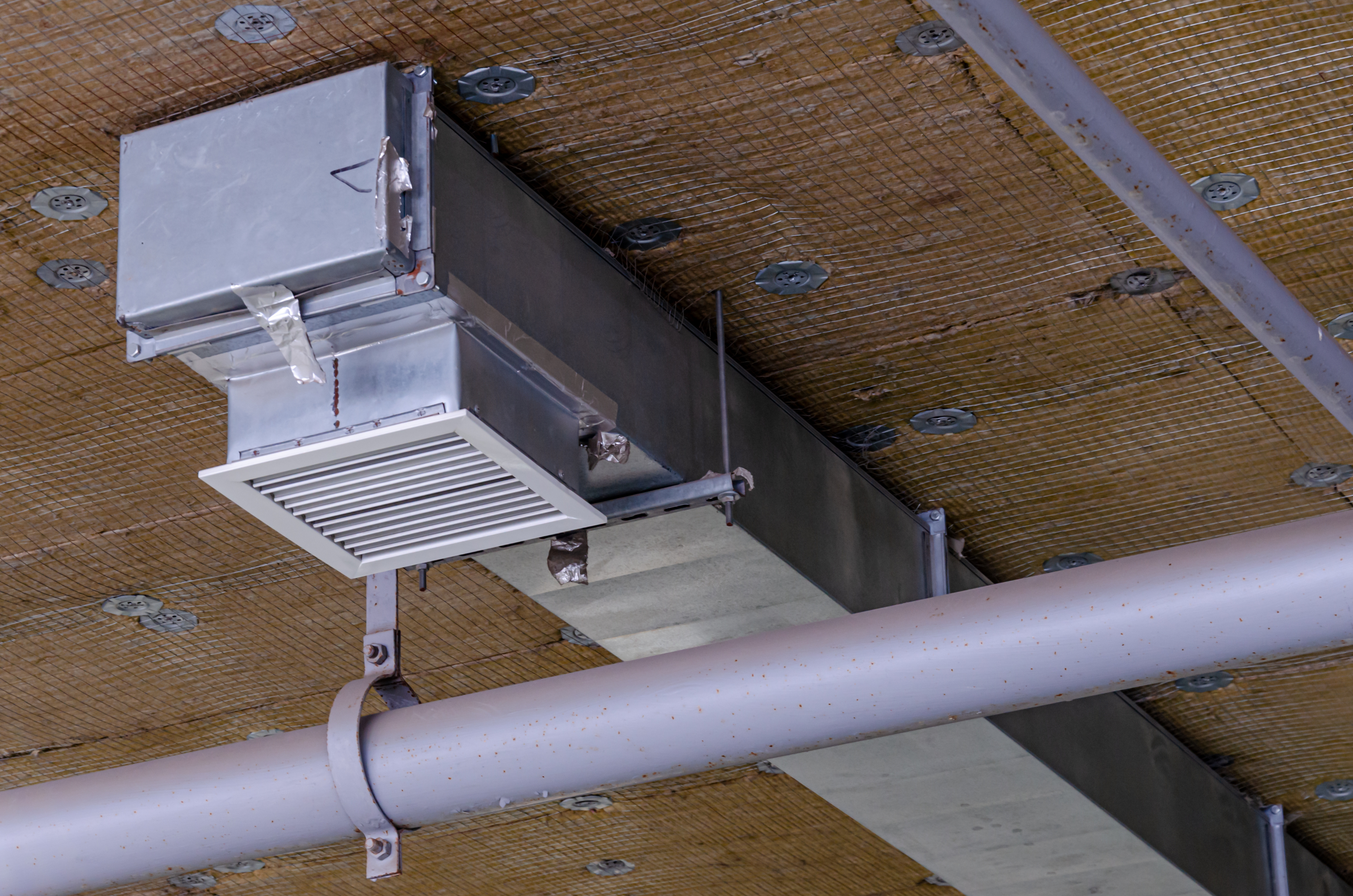

HVAC Duct Insulation

Prevent heat loss and improve energy efficiency by insulating HVAC ductwork. Proper insulation reduces energy waste, lowers utility costs, and helps maintain consistent indoor temperatures, keeping tenants and occupants comfortable.

Pipe Insulation

Insulate both hot and cold pipes to minimize energy loss, prevent condensation, and protect piping systems from temperature extremes. Pipe insulation is essential for reducing heat transfer and maintaining efficiency.

Storage Tank Insulation

Maintain stable temperatures and improve product viability with high-quality storage tank insulation. Ideal for industries that require temperature-sensitive materials or fluids to be stored safely year-round.

Chilled Water & Chiller Pipe Insulation

Optimize the performance of chilled water and chiller systems by preventing thermal loss and condensation. Insulation helps maintain proper temperature control and extends the life of your equipment.

Mechanical Room Sound Insulation

Reduce noise pollution and improve workplace safety with sound insulation for mechanical rooms. This helps meet OSHA noise regulations and creates a quieter, safer working environment.

Cold Storage & Refrigeration Insulation

Ensure consistent temperature control in cold storage facilities, walk-in freezers, and refrigerated spaces. Proper insulation is key for maintaining product integrity, reducing energy consumption, and preventing temperature fluctuations.

Additional Use Cases

- Industrial Facilities: Insulate equipment and systems to improve energy efficiency and maintain process control.

- Commercial Kitchens: Reduce heat loss and improve safety around high-temperature systems.

- Healthcare Facilities: Maintain controlled environments for sensitive equipment and patient areas.

- Educational Institutions: Enhance comfort and reduce energy costs in classrooms and administrative buildings.

Types of Insulation for Commercial Buildings

There’s no one-size-fits-all solution when it comes to insulating your commercial building. The best choice depends on your facility’s layout, energy goals, budget, and specific needs. Below are some of the most common and effective insulation types used in commercial applications:

Polyisocyanurate (Polyiso)

A high-performance, closed-cell rigid foam board insulation, Polyiso is bonded to facers on both sides — typically made from organic or inorganic materials. It’s ideal for insulating commercial roofs, walls, ceilings, and specialty applications. Its excellent thermal resistance makes it a top choice for energy efficiency.

✅ Best for: Roofs, walls, ceilings, and specialty areas.

✅ Benefits: Exceptional thermal resistance, moisture resistance, and energy efficiency.

✅ Use Cases: Flat commercial roofs, exterior wall systems.

Rock Wool (Mineral Wool)

Made from natural stone and recycled materials, Rock Wool is dense, fire-resistant, and offers superior soundproofing. It’s commonly used for insulating industrial pipes, mechanical rooms, water heater tanks, and areas requiring high-temperature resistance and noise control.

✅ Best for: High-temperature areas, soundproofing, and fire-rated assemblies.

✅ Benefits: Fire-resistant, excellent sound absorption, withstands high temperatures.

✅ Use Cases: Industrial pipes, water heaters, mechanical rooms.

Fiberglass Blanket (Batt & Roll Insulation)

One of the most common insulation types, fiberglass blanket insulation is made of layers of fiberglass placed between two sheets of paper or foil. It’s typically installed between wall studs, floor joists, and ceiling beams, offering reliable thermal and acoustic insulation at an affordable price.

✅ Best for: Standard walls, floors, and ceilings.

✅ Benefits: Cost-effective, easy to install, good thermal and acoustic insulation.

✅ Use Cases: Wall and floor joists, ceiling beams in commercial buildings.

Fiberglass Board Insulation

A rigid form of fiberglass insulation, this is frequently used to insulate HVAC ductwork. It provides excellent thermal and acoustic control while protecting against condensation and energy loss.

✅ Best for: HVAC ductwork and large mechanical systems.

✅ Benefits: Strong thermal and acoustic control, prevents energy loss and condensation.

✅ Use Cases: HVAC systems, industrial ducts.

Spray Foam Insulation

Applied as a liquid that expands and hardens into a dense foam, spray foam creates an airtight seal, filling gaps and hard-to-reach areas. It’s highly effective for reducing air leakage and providing superior moisture and thermal resistance.

✅ Best for: Sealing irregular spaces and preventing air leaks.

✅ Benefits: Superior air sealing, moisture barrier, high R-value.

✅ Use Cases: Walls, roofs, hard-to-reach areas.

Loose-Fill Insulation

Made from small particles of cellulose, fiberglass, or mineral wool, loose-fill insulation is blown or sprayed into place. It’s perfect for irregularly shaped spaces or areas with obstructions where other insulation materials can’t easily fit.

✅ Best for: Hard-to-reach or irregularly shaped areas.

✅ Benefits: Flexible application, fills gaps around pipes and beams, good thermal resistance.

✅ Use Cases: Attics, wall cavities, around obstructions.

Why Choose MultiService for Your Commercial Insulation Needs?

Proven Expertise

With over 30 years of experience, our team delivers precision insulation solutions tailored to your commercial facility’s needs. We understand the challenges of industrial environments—and we solve them.

Energy Savings That Pay Off

Our insulation systems are designed to maximize energy efficiency, lower operational costs, and deliver measurable ROI from day one.

Safety & Compliance First

We follow strict safety protocols and ensure full compliance with industry regulations. Protecting your team and your facility is always our top priority.

Fast, Reliable Service

We show up on time, complete projects on schedule, and minimize disruption to your operations. Your deadlines are our deadlines.

Customized Solutions

No cookie-cutter approaches here. Whether it’s HVAC ductwork, chilled water pipes, or large-scale mechanical rooms, we design and install the right insulation for your application.

Get a Free Quote Today!

Let’s talk about how MultiService can help you reduce costs, increase comfort, and protect your building.

Ready to Get Started?

Take the first step toward reducing energy costs, improving comfort, and protecting your facility with expert commercial insulation from MultiService Industrial. Whether you need insulation for HVAC systems, pipes, storage tanks, or specialized areas, our team is ready to deliver custom solutions that meet your needs and exceed expectations.

👉 Contact Us Today for a Free Quote!

Fast turnaround. Reliable service. Proven results.

📞 Call Now: 866-921-0434

📩 Or Request Your Free Consultation

Don’t let temperature variations disrupt your operations. Let MultiService Industrial install an efficient, cost-effective heat tracing solution that keeps you running through Virginia’s unpredictable climate.

Commercial Insulation Resources

Case Study: MultiService Soars on Dominion Energy Project

Discover how MultiService Industrial successfully completed a challenging 150-foot vertical insulation project for Dominion Energy. This complex job highlights the team’s expertise, safety commitment, and ability to deliver high-quality results in demanding environments.

The Best Commercial Duct Insulation

Learn about the best types of commercial duct insulation and how they can improve energy efficiency, reduce operating costs, and enhance comfort in your building. This blog covers key insulation materials, their benefits, and expert tips to help you choose the right solution for your HVAC system.

Case Study: Henrico Doctors’ Hospital Enlists MultiService to Insulate Large Diameter Pipe

Explore how MultiService completed an insulation project at Henrico Doctors’ Hospital. This case study highlights the team’s ability to work efficiently in a healthcare setting, ensuring minimal disruption while enhancing energy efficiency and system performance. Learn about the challenges, solutions, and results of this specialized commercial insulation project.